I left off with rain washing the neat little mounds of dirt back into the trenches – a disheartening sight. Trying to stay optimistic, Brad thought that we could just bring the trencher back out, and have it re-clean-out the trenches. Simple – right?

Sunday was warm and sunny, everything should dry nicely – right? We discovered the hard way that clay does not dry quickly. Clay that is just the right (or wrong) consistency is difficult to work with to put it lightly. Brad lined the trencher up, and as he started, he nearly lost the trencher in the trench. It was all he could do to get this 900 pound earth eating machine onto solid ground. Mary grabbed a slab of plywood to cover the trench for somewhere for it to go, and it nearly broke through that. We got it back on solid ground and realized that this was not going to work. The remaining work would have to be done by hand, the ground was just too unstable and unpredictable from all the rain.

We hosed it off, and returned it to the rental company. There was so much left to do, and it felt impossible and defeating. There were sections that had partially filled back in, other areas that had never gotten deep enough, rocks, roots, and clay that made the trencher useless.

As defeating as it all was, we were past the point of no-return. The wire was ordered and on its way and the power company was paid to move the power to underground. Turning back now would be foolish, but going forward felt impossible.

There was nothing to it but to do it. So we slowly plugged away at it. Brad’s good friend Frank came to check out our problems and progress. Frank, being retired would pop in during the week and put an hour in here and there.

Before we got all the trenches finished – the wire arrived! This is what 400 pounds of wire looks like. Probably about 2,400 feet of wire!

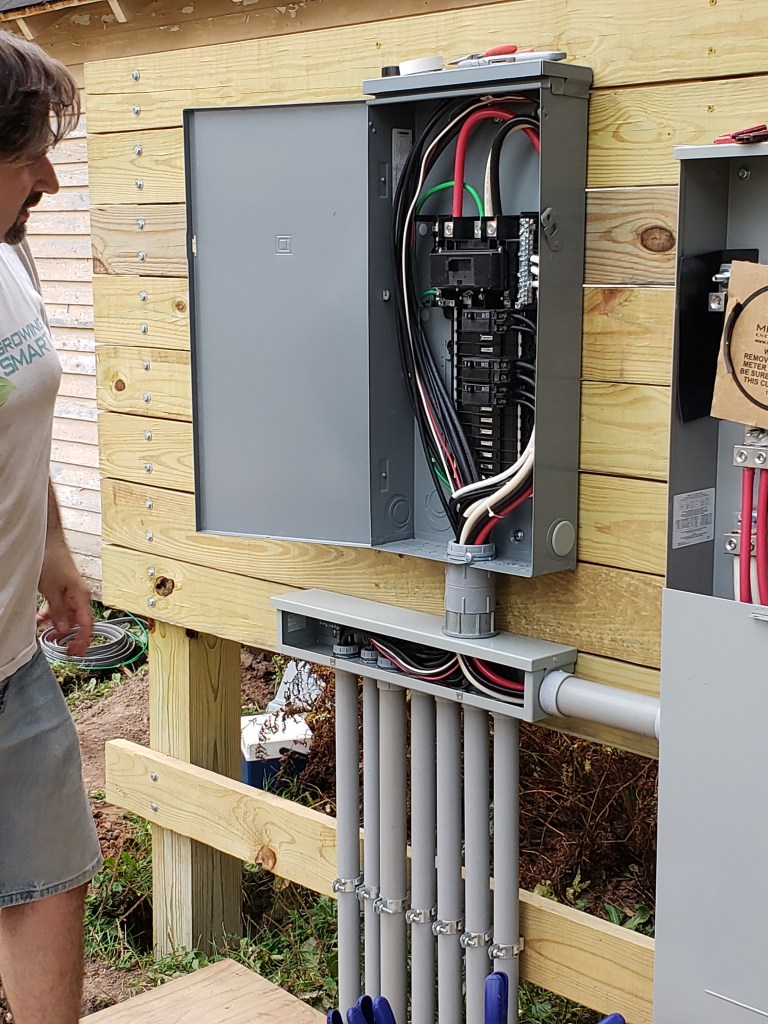

Clearing the trenches was anything but easy. I told Brad that if we had had to do all this by hand – we would be staying overhead! Hard work, made it slow going, and we were in fear of trenches collapsing again once we had them cleared. Frank had the smarts to suggest that once we had a trench cleared, that Brad start running the wire in that trench. If it re-collapsed, bit deal, the wire was in it already. So that’s how we proceeded, one trench at a time. We had 7 trenches to take care of total, ranging from a few feet to over 100 feet long.

Since I was running the camera, there aren’t any of me inching my way across the driveway with the pick-axe, something my back later told me it did not approve of. We all put in our share of sweat equity, and Frank’s help was invaluable not only the labor itself, but the motivation he provided.

Plugging along we finished laying the lengths of wire in the course of a week.

This is a tree root.

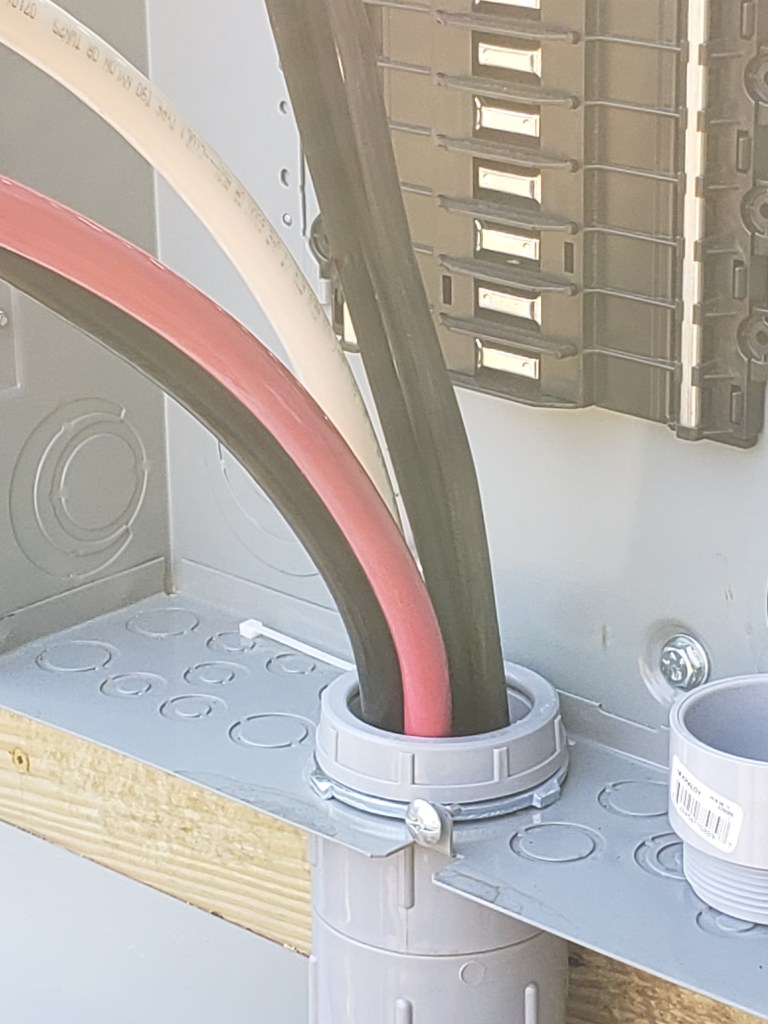

Next hurdle – a spaghetti of wires that had to fit through conduit and make a bend. Industry specs say that you can fill the conduit 60% full. Brad had calculated that he would fill something like 59.8%, piece of cake, right? Um – sure.

4/0 aluminum

23 wires ranging in size for 3/0 to #10 need to fit through here!

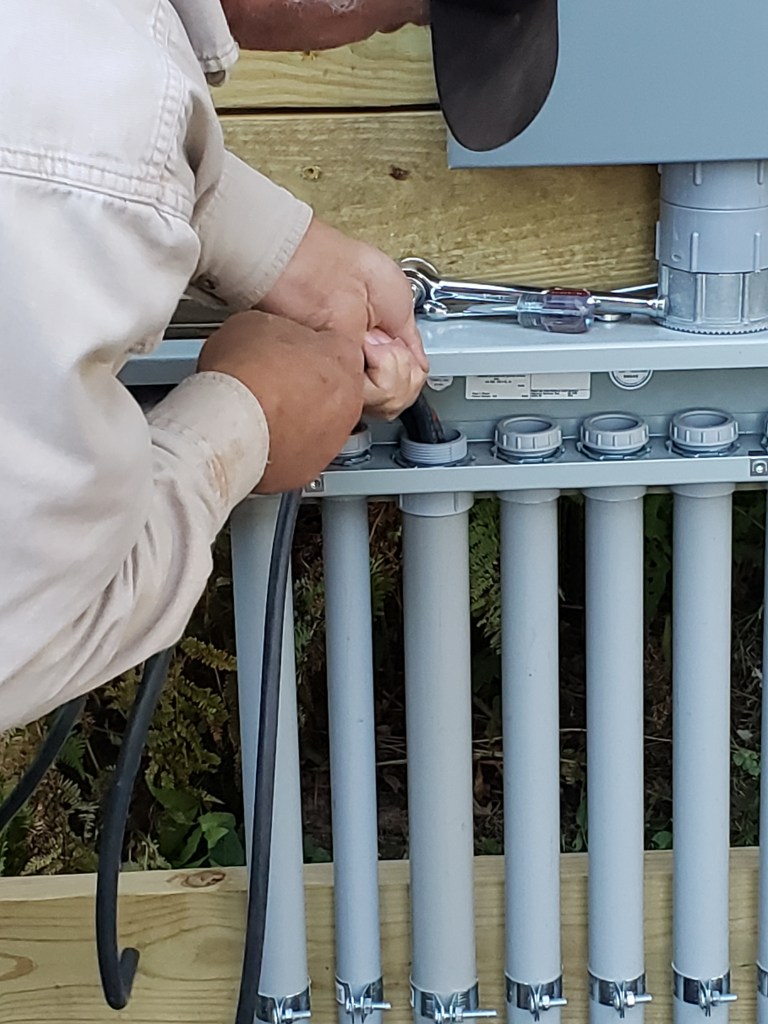

Each conduits has 4 wires coming up it, except one for a future garage.

Thankfully we worked on this in warm weather making the wire and coating more pliable. Still there were lots of prayers said and expletives dropped. While 60% sounds like apiece of cake, 40% adds up fast with all the tiny voids remaining when you pack cylinders next to one another. Then we were working with 3/0 to #10 wire (nothing tiny). The sheer size of some of the wire made it difficult to work with. Painstakingly Brad wiggled and shoved each wire. The 4/0 did not go through the conduit with all the other wires. It was on the run to the main house. We would get to deal with that later.

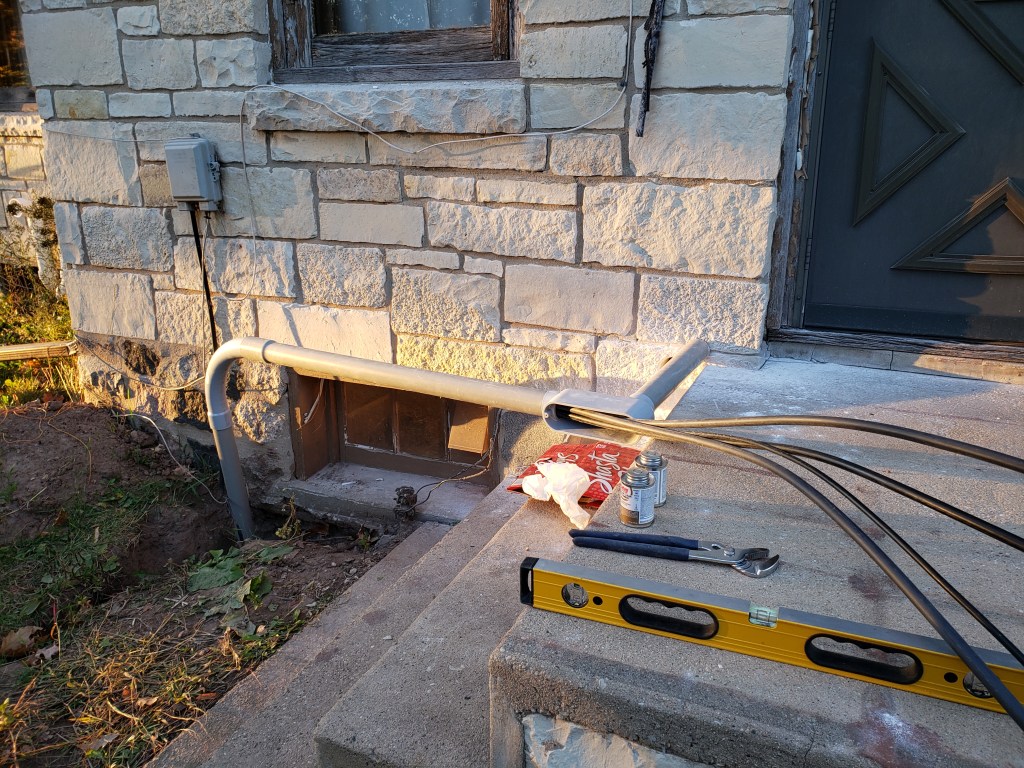

The rough lines were laid in all the trenches. Brad wanted to bore through the stone while we still had power at the house to avoid running extension cords across the yard, that meant getting the hole bored before the power company came. After doing some serious research Brad found a diamond core bit to carefully put a hole in the lannon stone. After about an hour of drilling he made it through the stone. He did wear hearing protection, but should have had knee pads since he heard something pop and is dealing with a sore knee 2 months later.

Getting the wires into the house happened AFTER the power company came, but because I’m focusing on the house right now I’m going to mess with the time line and continue on about wiring the house for now. The power company is a story in itself.

Getting the wires into the house was almost more challenging than the main panel. We were dealing with the largest wires of the project. For cost effectiveness Brad ran aluminum to the buildings since it is cheaper than copper, but since there is more resistance with aluminum a larger size is required for the same load. So a 4/0 aluminum carries about the same load as 3/0 copper. (180 amps vs 200 amps, and then there is an exception in the code allowing for use of 4/0 aluminum (which carries 180 amps) for 200 amp service on dwellings.)

Don’t get me started on the numbering scheme makes my head hurt. Anyhow, here is a quick explanation as I understand it from Brad. 4/0, 3/0, etc is read as 4 aught. From him (I don’t know electrical) they (electricians back in the 1800’s who invented the numbering scheme) eventually ran out of numbers, because the original sizes get bigger as the number gets smaller. So #10 (10 gauge) is smaller than #8 (8 gauge). Apparently wire got bigger after the numbering scheme was invented and in heavy use, the industry hit 0 at some point and there needed to be a way to identify the sizes larger than 0 (which is big not small). The larger wire doesn’t follow the same numbering scheme, because 4/0 is bigger than 3/0. Confused? Me too! That’s why I was the trained monkey doing the labor and not in-charge of figuring any of this out.

Anyhow – thankfully October had some nice warm days to work with the big 4/0 wires. They did not want to cooperate. More prayers, expletives, and more prayers, and having to let it sit overnight and come back at it the next day. Finally – success! Hallelujah!!