It was mid-October in Wisconsin, the project had now become a race against Mother Nature to finish. The Garage was complete and so was the main house. We needed to connect the other buildings before it became intolerably cold or we had a foot of snow. Mother Nature in Wisconsin is bi-polar and she’ll do what she wants when she wants. October can be mild, or wet and cold, or snowy. We had 5 connections left to make, with how fast the rest of the project went, it was a bit concerning that we still had so much left before winter.

When Brad was drilling through the stone and hurt his knee – it was still giving him grief. So I scolded him and told him he couldn’t be kneeling. He explained that he needed to, to get the project done. I reminded him that Brandon or I could kneel for him – ha! So when it came to push the wire into the well vault, and to putting hydraulic cement, and rubberized sealant on the connection, guess who got to do it? (I really did do it, Brad just doesn’t take many pictures.)

Hole for the service entrance into the well vault.

Brad drilled into the concrete vault that houses the well to run the line, it went through conduit. We then patched the excess hole with hydraulic cement and coated it with rubberized sealant.

Next was the machine shed. This was the first time that the machine shed had power – ever.

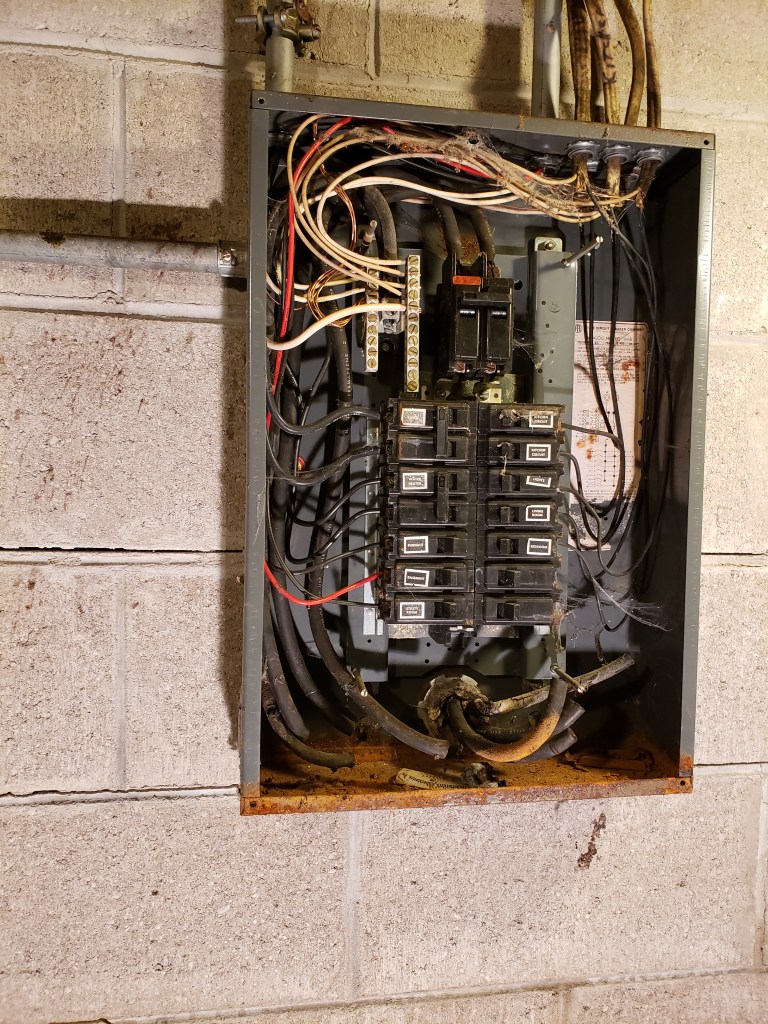

The weather remained warm with cold days here and there. Brad wanted to start work on the Guest House next. Depending on what we found it would require lots of wait time. The current entrance was underground, and we learned about all the wait time with the well. If he could, he would reuse the underground entrance and just make sure it was sealed well. If it looked sketchy we would abandon the old entrance, seal it off, and enter the house above ground (with buried cable). With all the wait time and the days getting shorter and shorter it seemed foolish to have Brad working on exposing the current entrance. It took no skill, just being careful. So I finished hand digging to the foundation and down the 24″ that code requires. I exposed the current entrance and we realized that we were not getting the cap off the end of the galvanized conduit that entered the basement. Brad pulled the current panel which had tell-tale signs of water somehow getting in, and far too easily pulled the conduit out of the cinder block wall. Brad went back to the skilled part of the project while I finished cleaning out the hole and cleaning off the cinder block in preparation. Te rubberized cement popped off the outside – I don’t think it is supposed to be that easy.

I’m no electrician, but I don’t think breaker panels should be rusty.

The old rubberized sealant – popped off perfectly.

After some rain we needed to make sure the cinder blocks were thoroughly dry before sealing the hole.

While I cleaned out the Guest House entrance, Brad continued to work on the other buildings – first the barn and then the granary on Halloween.

That’s me – filling the Granary trench

New service entrance on Granary

The new connection would enter the house above ground and the go to the basement, so the old hole had to be sealed. This was a process of applying 2 coats of hydraulic cement inside and out, and then 2 coats of rubberized coating on the outside. We wanted each coating to dry at least 24 hours since we had less than ideal drying temperatures. With the underground wiring entering the Guest House above the ground it would greatly reduce the chances of water entering through any of the connections. Once the old entrance was sealed and the hole for the new entrance drilled Brad went to work on the inside.

Old entrances sealed!

New entrance.

Peek-a-boo

Driving ground rods

That’s me – more trained monkey work

Preparing PVC conduit for connections

Thank goodness for extension cords

Finishing gluing the connection

Early sunsets = work by light

Twilight on the hill

Finishing touches – notice the basement lights are on!

With finishing the panel in the Guest House, the underground wiring project was DONE!