We finally got the call from Jack that he was ready to pour the basement floor!!!

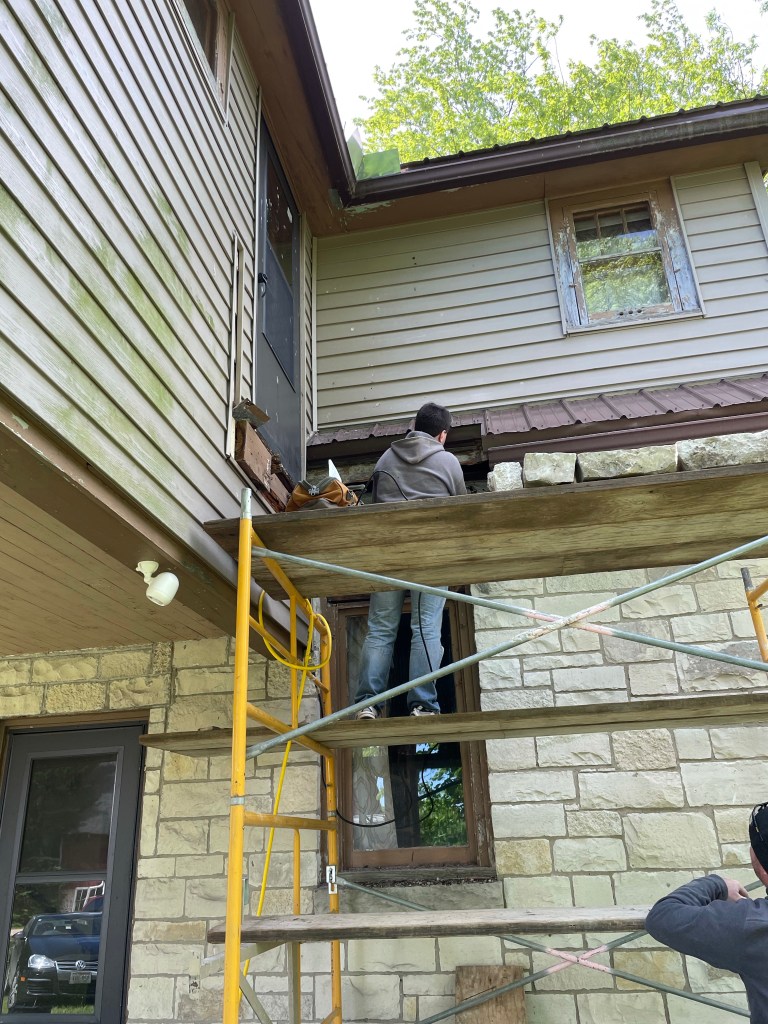

We had originally started talking to Jack last year about this time in November 2020. He came and looked at the project and was willing to do it. It wasn’t a big project and our schedule was really flexible. He told us we should talk to him sometime next spring (spring 2021). We touched base with him in spring, and after a conversation decided that it would just be best if he waited until the stone mason was completed with his work to avoid them getting in each other’s way. Darren, the stone mason started in May and the 1 day job turned into 3 weeks (he was awesome, the scope was much bigger than he or we anticipated). (See Pandora’s Box for that story.) So Jack figured he would start sometime in June.

June became July, he had a break in his schedule and was able to come do the transit work. That was done, and then we were gone parts of early August and that messed schedules up. Time was ticking away to when we were loosing our help. Our youngest would be heading off to college, and Jack had been planning on Brandon running the wheelbarrow.

About a year before we originally talked to Jack about this project we had talked to another friend, who works with concrete on an industrial scale for his real job, and also does some stuff on the side. He thought we should take some of the dirt out and put a layer of gravel down for footings. We asked Jack his thoughts on that. Looking at the clay that had become hard packed over 75+ years, he said we were better off leaving it alone. If we dug too much and had to refill, we would never repack as hard as this clay was now. We were not going to complain. The thought of hauling 40 cubic feet of dirt up the steps was not something we looked forward too, so we were only too happy to accept his rationale.

For anyone who’s eyes just bugged out of their heads and is envisioning the floor failing, know that there is a ton of red clay on the property (and in the basement floor). When we dug the trenches we had to use a pick-axe to get through the packed clay. There is nothing going in this room but storage, and the floor will be fairly thick (keep reading).

Transit line.

We did have to dig a bit out by the door, so cement could be added without having a step up into the room.

We were home, and then some contractors working for Jack on his own DIY projects finally had a break in their schedule which had a domino effect. Finally a week and a half before Brandon left for college our schedules aligned. Hallelujah!!!

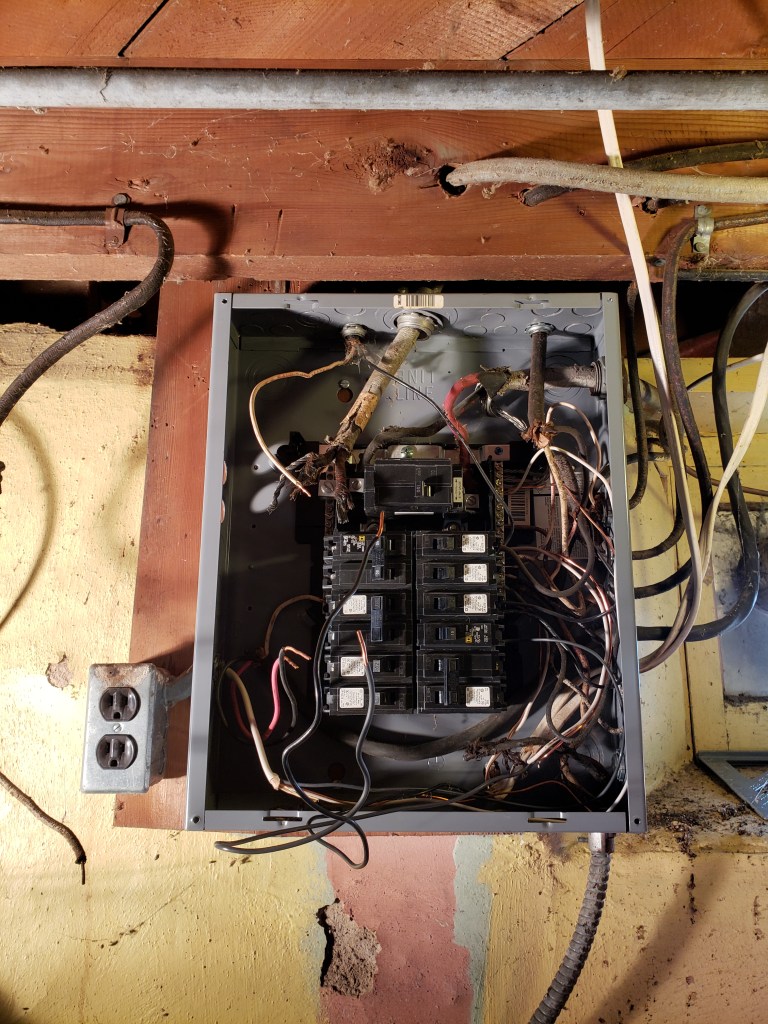

Brad took the door off the room so that it wouldn’t be in the way. Jack re-checked the transit work and we laid a vapor barrier and built a chute. The cement truck would be coming the next morning!

It had been dry for days, and then it rained overnight (the night before the cement truck was coming). This didn’t get the basement wet or deter the work. It just made the ground softer. The approximate weight of an empty cement truck is 13 tons. This truck was traveling light with only 4 yards of concrete (which adds nearly 8 tons). So we had approximately 21 tons driving across our damp, soft, squishy yard. (Not complaining, we were glad to finally be getting this done, just a bit surprising to see what 21 tons does to a lawn.

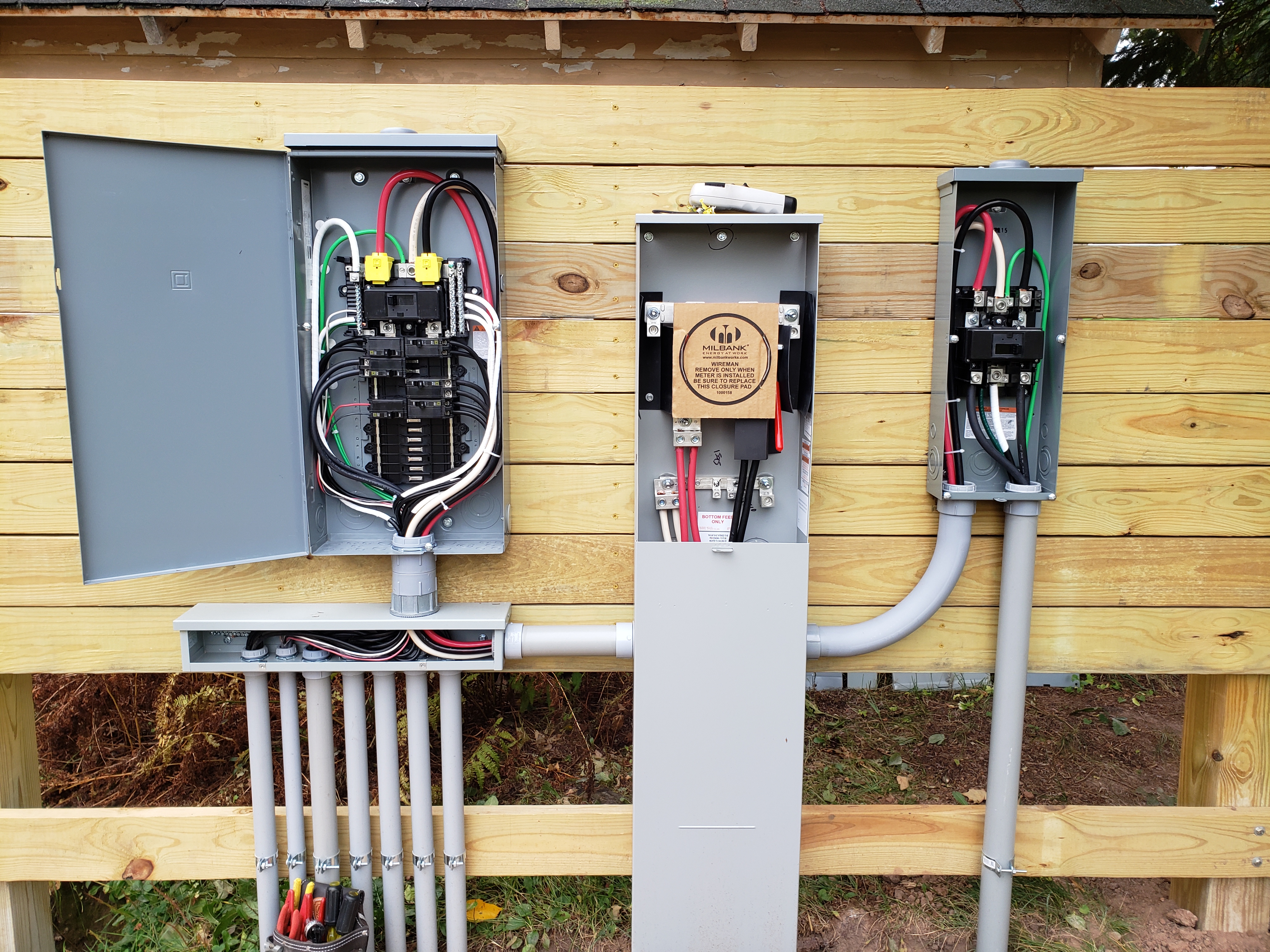

Now that you can see where the cement truck drove I’ll explain a little better why the garage was on hold.

It took a bit to get the flow just right, but then we were in business!

Brandon was a huge help and worked really hard. Jack was phenomenal. While the basement was large enough to be daunting (to someone who has no clue what they are doing) it was tight quarters to work in. Brandon couldn’t even turn the wheelbarrow around, he had to pull it back to the chute.

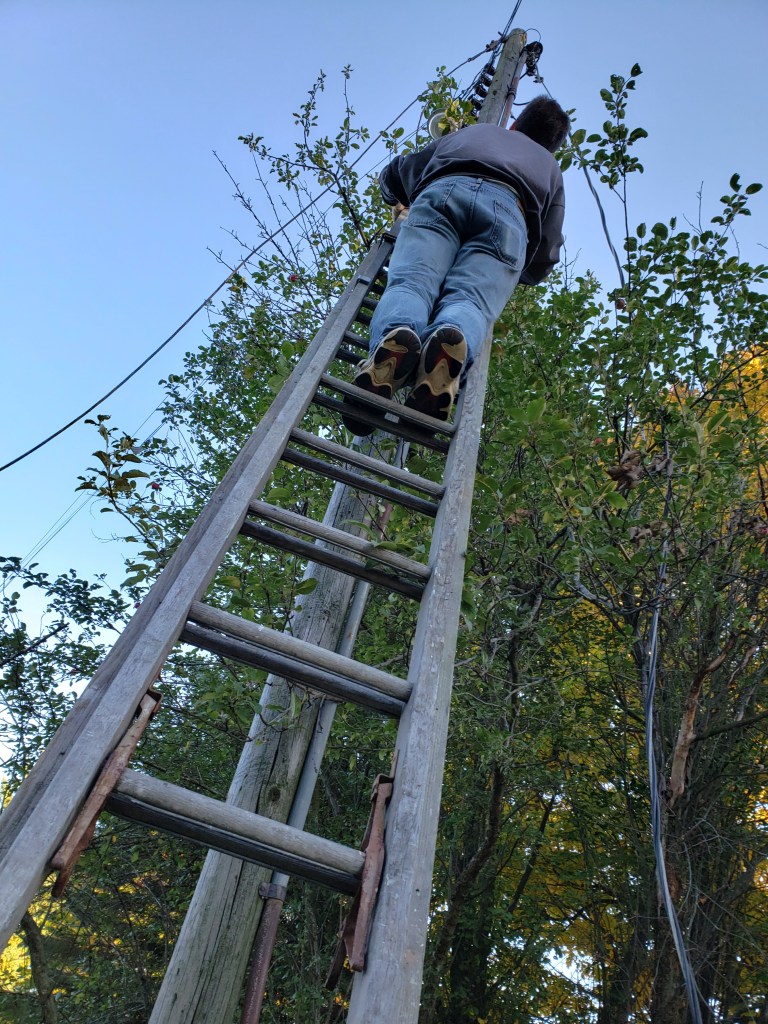

Brad and Brandon ran the wheelbarrow, and communicated with Marty the cement truck driver, and dumped their wheelbarrow full where Jack told them. Jack shoved, sloshed, and half kicked this gravely semi liquid – semi solid pile of slop around to where he wanted it. As it began to set-up it would hold its shape a bit. Because of the design of the basement, Brandon had to slosh through the concrete to get out. Jack worked his way to the chute and then using the ladder came out the window.

“how am I supposed to get out?”

Brandon stepped through the concrete to get out (Jack told him to), Jack worked himself over to where the chute was, took that out and handed it out the window, and then exited the basement through the window.

Jack calls a Dinosaur Turd

While Brad, Brandon, and Jack worked on cleaning everything up outside (including themselves) the brand new floor was was drying just enough that Jack could come back and smooth it out.

Jack smoothed the floor 3 times in addition to the initial leveling as it was poured. He has machinery that takes the back breaking labor out of it, but decided that the area was small enough he would rather do it by hand than deal with getting the equipment down the stairs.

After about a week we were able to walk on the floor. The difference was amazing, not only the look but also the moisture level in the house and the smell.

Jack did an amazing job! We love how it looks. We were so thankful that Brandon was able to help. One more job done!