Disclaimer – I reserve the right to reuse this title again in some way shape or form. Yes, I know that could get confusing, and I will try my best to differentiate. Here’s the deal – we’ve discovered when doing work on an older home, you open a wall, rip up a floor, etc, and you find that there was some cosmetic band-aid covering a “slap & a promise” (a half done job that the owner may or may-not have intended to return to and do appropriately) or some ugly big repair that a half-assed job would make it good enough to do. So your 1 simple job turns into 1, 2, 3+ jobs depending on your own level of OCD for things being right, time, money, and being able to look the other way.

Ok – on to Pandora’s Box

Last fall -actually last year we started the search for a mason. There are lots of people who can work with concrete. The number that can work with stone, not just veneer, is shrinking. We found 1 company who came to look at our project. He gave us a quote of about $16,000 (no that’s not a typo).

We did more looking around, for someone working on their own. Found 2 who were retired (no help there). I then turned to our mechanic. The guy has lived here his whole life, is 2nd or 3rd generation in the area, his dad started his small garage and his son is now taking it over, and for a period in the 80’s he was the town mayor. The guy knows pretty much everyone, or has at-least heard of them. He gave me a name & number, and told me the guy does great work.

Darren (the mason) came out, looked it over, gave us a quote of under $1,000, plus a couple hundred in materials, and told us to call him in the spring.

Spring came, and getting in contact with him was an exercise in patience. While we were waiting for him to return our calls we started to discover that there were questionable areas. We started with these areas desperately needing attention.

When the house was built (we guesstimate sometime between the 2 World Wars) the stone was placed directly on the wood frame of the windows.

Kinda hard to tell, but this core is about 6″ thick of solid limestone. Now when the house was new all that weight resting on the wood was no big deal, but wood and stone are not a good combination to have resting on one another due to moisture, rot, etc. Over the years under the weight of the stone some of the wood was starting to sag and the mortar was actively cracking over 4 windows with the stone starting to drop. Add to that water issues around 3 corners of the house that had deteriorated the mortar in the field-stone foundation. As we started looking 5 more windows had the mortar cracking. In talking to Darren, we decided to do all the windows and doors (minus the double north window that already had a steel header and the door under the patio). There were only 3 windows without compromised mortar and we figured with our luck it would start to fail right after he retired.

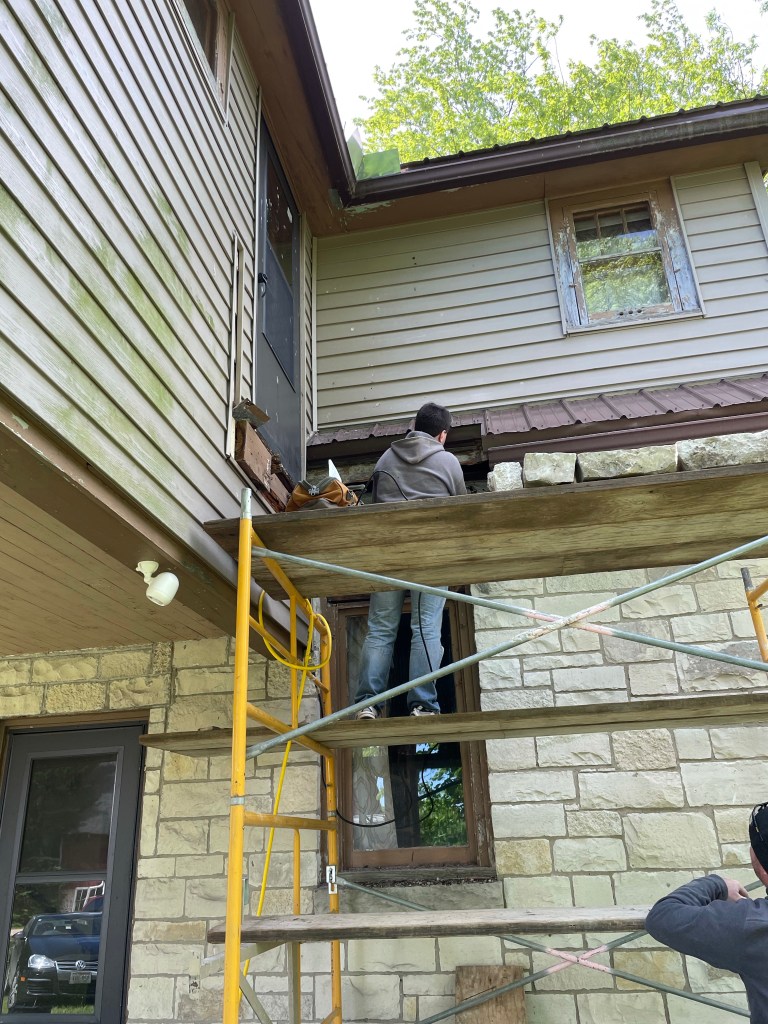

So basically he would removed the blocks above a window or door, wrap the piece of angle iron in while aluminum and put it over the window, and then reassemble the jigsaw puzzle of blocks. It took him a bit to get into the rhythm, he was used to working on new builds, but once he got the feel for it, he really started to zip along. It went pretty much as expected. Then Pandora reared her ugly head.

Behind where the balcony had been the wood was rotten.

The frame on top of the bathroom window (on the north side of the house) was actually starting to rot. So Darren had Brad cut some wood and replace the rotting wood with something solid.

The mortar was by far in the worst shape where the deathtrap of a balcony had been. Once Darren disassembled the jigsaw puzzle, he found the wood rotten above the window and it went up into the soffit.

Bathroom window with new wood in frame.

Before new wood could go in, the old rotten wood had to come out. It wasn’t that cooperative. Brad tried pulling the nails, but no dice. Time for the Sawz-all! After a broken blade he got the board out. Getting the new board in was a bit tricky, but between the two of them, Brad and Darren got it in.

North basement window

Same window – close-up

We had been debating when we should do something with the basement windows, and what. Well, walking around on the north side we discovered that the block was dropping over one of the basement windows. Ugh!

So now what? The easy answer was that as long as we had Darren out, and he had time, he should fix this and any other basement windows. There was even more weight on these windows than the ones he was working on, and they were done the same way as the others originally had been.

The obvious answer was what Brad had been voting for all along, glass block. It would be solid and could bear the weight of the stone pressing down on it. I really didn’t want to go glass block it just seemed too industrial, but I conceded that it was the best option for what we needed. We started virtual shopping, in our area we cold only get the wavy glass block. Ugh! I wasn’t a fan to begin with, and now the thought of only seeing vague shapes when I looked out the basement windows was less than exciting. I turned to Google, and found a dealer that sold clear glass block. Yay! They were in Illinois – 4 1/2 hours away. Ugh! Darren was making good progress, we had to make up our minds, and fast.

We decided to go clear. We could have the dealer ship it to us, but it would add another week, and Darren was going to be ready for it in the next few days. He had Brad remove one of the basement windows (frame and all) so he could see what he was up against.

Needless to say we were a little nervous about taking the support away from the stone above. My mind reeled, what if it fell down. Darren calmly told us, if it fell off, he’d just put it back up. (I guess, it still made me nervous.)

Brad took a day off and we made a road trip to Morris Illinois.

Showroom

Loaded & ready to go.

Our drippy drive home – all the way.

We placed our order in advance, and had to wait a bit to pick it up. It was pretty non-de-script in an industrial park. We stopped off and saw our brother-in-law and nephew on the way home, since Morris was only a half hour away from them. On the way home it poured and poured.

We realized in transit that Darren couldn’t finish. Half the basement is still dirt, and we have someone coming to pour a concrete floor, and he needs to have the cement truck put it’s chute through one of the basement windows in particular. We had checked with him about going down the basement stairs since it is a straight shot. No such luck since the truck cannot get close enough due to the patio.

The dirt basement floor that’s slated to become concrete – I’ve convinced Brad to let me keep a small section dirt and seal it off from the rest of the house for a small root cellar. We had a conversation with Darren about what to do for the window that would be in that room since it would have an inlet and outlet vent, and it would be impossible to complete that opening with glass block. At first Darren suggested bricking the opening up, and the more he thought, the less he liked the idea since there wasn’t a single brick on the house (except for the chimney). After a conversation, he sent us on another shopping trip for thin, split-face Mountain stone (aka thin, split-face granite). We had picked that up earlier, and when we returned with the glass block, Darren had removed the coal chute and stoned it up. (The inside was cinder block, but who would know!)

Future root cellar & where concrete will enter the basement.

No more coal chute.

Brad finished removing the original windows and Darren continued to make progress on the upper stone, and the lower windows, juggling more than one window in progress at a time. Quite a difference from when he started and worked on one window all day getting the feel of how to rip it apart and put it back together again.

One final thing before Darren temporarily left us. The corners.

The North East and South West corners were pretty simple as piecing back together a puzzle made of fieldstone can go. Then there was the North West side. This was the corner that had been without a gutter above, and leaked the worst in the basement.

Darren started digging to get to solid mortar. He asked us to dig down 2 more feet from what he had already dug out. He dug down all the way to the base. (There’s no footing under the old fieldstone basement. A huge stone was placed and built upon from there.) The years of water and the roots against the foundation had completely disintegrated the mortar over the years turning it to basically sand. Darren took the puzzle apart, and put it back together with a bit more mortar than original. He told us to leave the plywood to protect the fresh mortar from splashing as it cured.

Darren is finished, for the time being. The tuck pointing on the main stone looks great! There is so much more light in the basement. Now to get ready for the basement to be poured.

Hi Mary & Brad! Can we get an update soon?

Cheers!

Bas

LikeLike

Bas,

Thanks for the nudge. I’ve got a new post up and will be adding more soon.

Mary

LikeLike